The hydrogen that dreams are made of.

Validate hydrogen technologies under realistic operating conditions – safely, efficiently, and sustainably for your test environment.

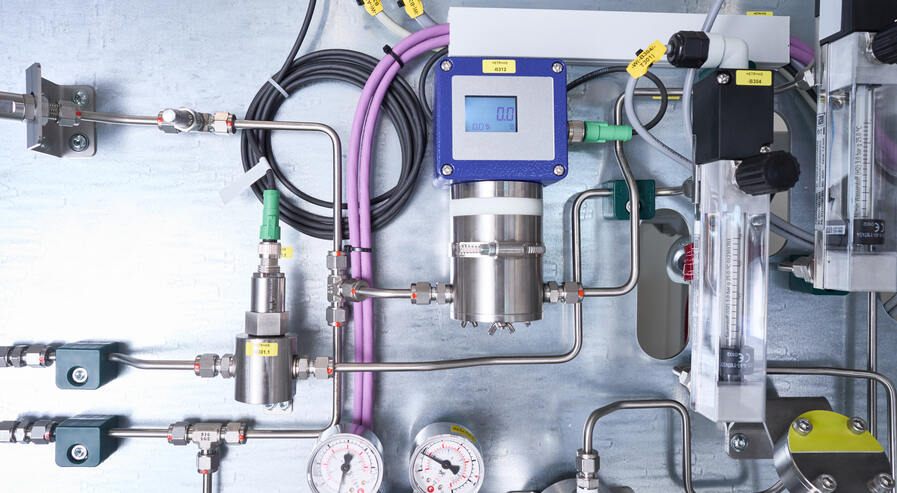

The H2EC series of electrolysis test benches enable precise, safe, and reproducible testing of hydrogen technologies – from individual cells to large stacks. With modular architecture, sensitive measurement and control technology, and a comprehensive SIL2 safety concept, they offer a professional platform for research, development, and quality assurance. Whether for performance analyses, material characterization, or long-term testing, the H2EC test bench delivers stable, reliable data, supporting innovation along the entire hydrogen value chain.

Advantages

- Modular & flexible: suitable for PEM, AEM, or AEL technology

- Comprehensive safety concept: SIL2, H₂ detection, automatic inerting

- Precise process control: up to 50 bar at up to 90 °C, sensitive flow control

- Fully automated test sequences: sequence editor, long-term tests, real-time control

- High-quality data acquisition: extensive measurement, analysis, and export functions

Application

- Research and development of new materials, catalysts, membrane structures

- Characterization and optimization of individual cells or stacks

- Quality and service life testing in industry and series development

- Validation of operating strategies (start/stop, load cycling, high-pressure operation)

- Energy, automotive, and chemical engineering (e.g., power-to-gas, H₂ infrastructure)

Faster electrolysis validation.

Modular test bench for electrolysis & cell research

The H2EC test bench is designed as a modular, flexibly expandable test system and supports a wide range of electrolysis technologies – from PEM to AEM to AEL. The configurable architecture allows precise control of temperature, pressure, flow, and cell voltage, creating realistic conditions for performance, material, and service life studies.

Optional integrated modules such as a temperature control unit (-30 to +200 °C), high-performance DC power supply, EIS analysis, cell voltage monitoring with up to 800 channels, or expanded DAQ systems with I/O terminals enable customized test setups for research and industrial development.

Highlights:

- Modular for single cells & small stacks

- Customized solutions for larger power or pressure ranges

- Precise control of temperature, pressure & water circulation

- Ideal for material testing, efficiency analysis & comparative studies

SIL2 safety & fully automated test procedures

The integrated SIL2 safety concept of the H2EC ensures that no explosive atmosphere can develop. Highly sensitive H₂ sensors, automatic inerting, fail-safe valves, and a dedicated safety PLC guarantee maximum operational safety – even during long-term tests around the clock.

With the AIP-MCS control system, even complex test series can be programmed using a sequence editor and executed automatically. Real-time visualization, comprehensive data recording, remote access, and clear alarm messages ensure maximum user-friendliness and process stability.

Highlights:

- SIL2-certified safety architecture

- Automatic shutdown & nitrogen inerting

- Fully automatic test sequences & real-time control

- Remote access & professional data analysis