Mastering drives and components – EMC-optimized down to the last detail.

Test electric motors, electric axles, and key components under real EMC conditions – precisely, flexibly, and in compliance with standards.

AIP's EMC test benches enable high-precision testing of electric drives and central high-voltage components directly in the EMC chamber. From electric motors and complete electric axles to battery modules and inverters, the systems deliver reproducible measurement results, controlled immunity tests, and outstanding EMC performance well below the applicable CISPR limits.

With integrated drive units, sophisticated shielding architecture, and flexible expansion options, electrical systems can be realistically loaded, controlled, and evaluated – without compromising EMC cleanliness, efficiency, or accuracy. AIP thus provides a powerful platform for the development, validation, and certification of modern electric drive technologies.

Advantages

- EMC-optimized test design: >6 dB below CISPR 25 limit

- Expandable for electric motors, electric axles, and HV components

- High performance: motors up to ≥ 120 kW, > 3,000 Nm

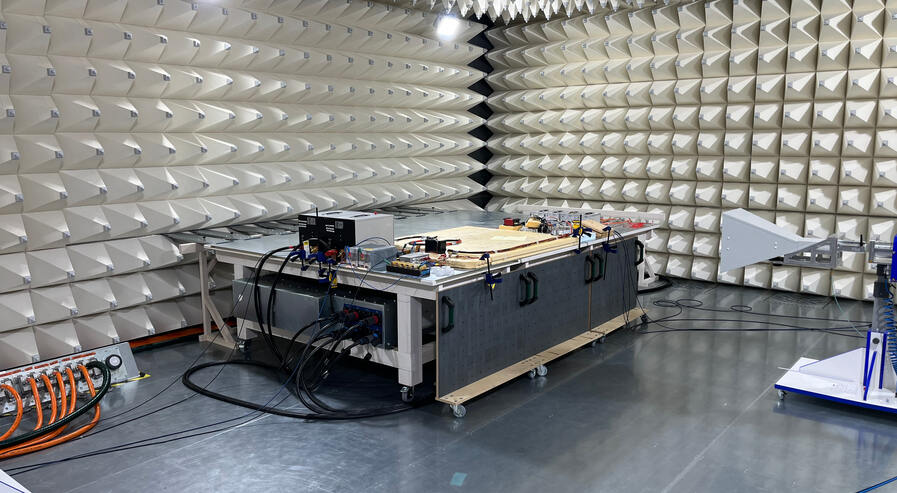

- Flexible installation: mobile setup between EMC chambers

- Integrated automation with MCS system and open interfaces

Application

- EMC testing for electric motors, electric axles, and powertrain modules

- Validation of inverters, DC/AC power electronics, and HV components

- Functional and endurance tests in the EMC field

- EMC battery measurements and HV energy management tests

- Development and approval tests according to CISPR 25, LV123, and OEM standards

Precise EMC testing at component level

Powerful load simulation for electric drives in the EMC environment

AIP's hydraulic EMC E-axis testing technology enables realistic drive simulations under precisely controlled EMC conditions. Highly dynamic hydraulic axes allow torques in the range of several thousand Newton meters to be applied with precision – ideal for testing e-axes, e-motors, or inverters under high loads, changing torque profiles, and demanding EMC field strengths.

The hydraulic solution is particularly suitable when maximum power density, fast load changes, and robust continuous load simulation are required. Thanks to shielded cable routing, EMC-optimized valve technology, and precise force and displacement measurement, the system remains low-interference and reproducible, even under extreme test requirements.

The modular design allows the test bench to be flexibly adapted to different axle and motor variants – from compact electric axles to heavy commercial vehicle modules.

Highlights:

- Highly dynamic, hydraulic load simulation for extreme torques

- Ideal for EMC testing of e-axles, e-motors, and inverter systems

- EMC-optimized hydraulic architecture for minimal interference

- Precise force, displacement, and pressure control for reproducible test profiles

- Modularly expandable for different axle configurations and vehicle segments

Fully electric drive simulation directly in the EMC chamber

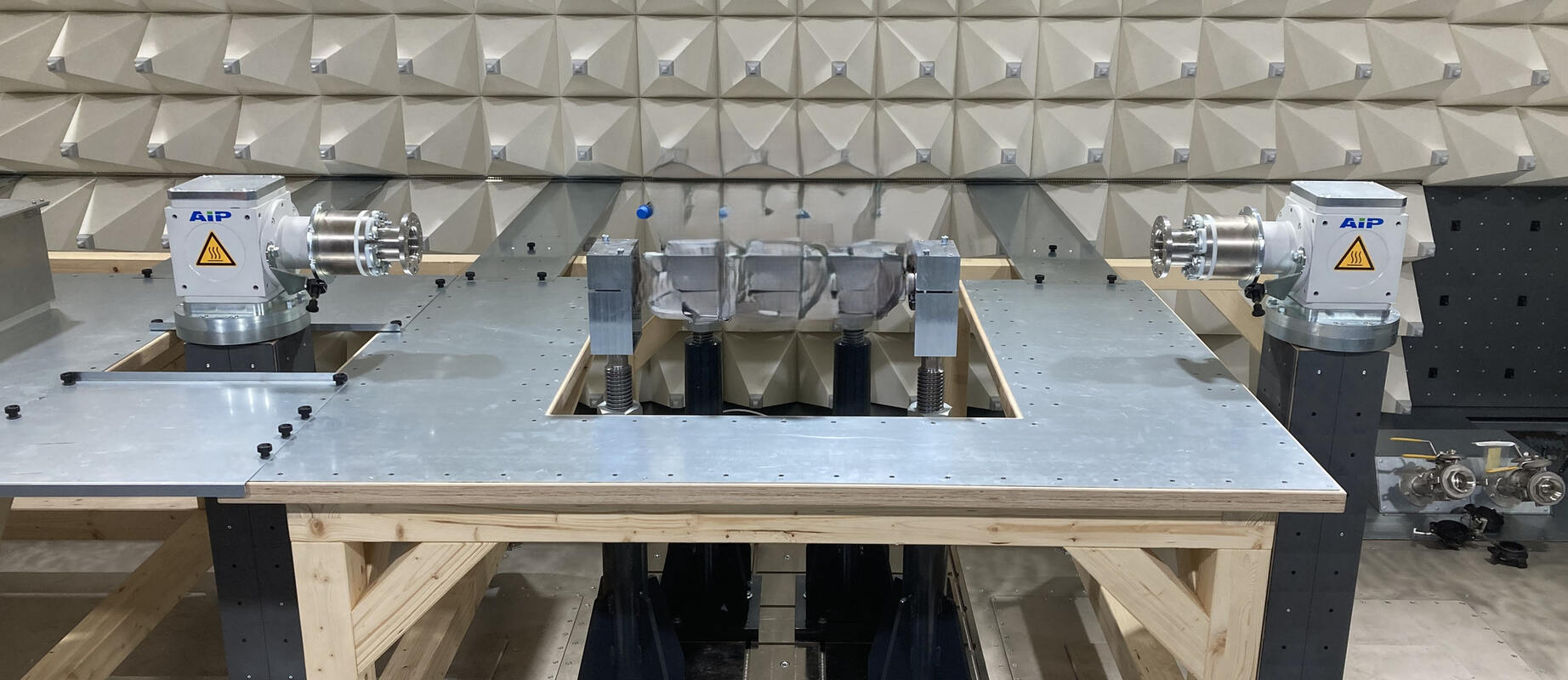

AIP's EMC electric motor test bench enables powerful electric drive units to be operated inside the EMC chamber for the first time.

The integrated 120 kW drive unit (S1) generates realistic torques of over 3,000 Nm, precisely controls speeds via the MCS system, and simulates real driving conditions.

The direct integration of the drive train into the shielded environment eliminates the need for complex chamber feedthroughs, drastically reducing interference. Measurements are >6 dB below the CISPR 25 limits – a benchmark for EMC-compliant drive testing technology.

Thanks to preconfigured interfaces, the test bench can be expanded into a full-fledged e-axis test system at any time – including bidirectional load simulation, inverter tests, or customer-specific torque setups. The compact modules are also mobile and can be exchanged between chambers without tools.

Highlights:

- Integrated drive unit in the EMC chamber

- 120 kW continuous power, > 3,000 Nm, up to 1,800 min⁻¹

- 10 dB below CISPR-25 – excellent EMC performance

- Expandable to a complete e-axis / inverter test environment

- Highly flexible: interchangeable between chambers, can be dismantled without tools

EMC-compliant test platform for all high-voltage components

In addition to drive units, the AIP portfolio also includes test benches for batteries, inverter modules, charging electronics, and other HV components. These systems combine EMC-optimized shielding architectures, filtered power supply, and flexible test environments to perform functional and immunity measurements under real-world loads.

Battery modules can be charged, discharged, and thermally controlled in a controlled manner. Inverter modules and power electronics can be tested for oscillation behavior, immunity, and conducted emissions. All components can be seamlessly integrated into the AIP-MCS automation system with open interfaces such as CAN, LIN, and Ethernet.

Highlights:

- EMC battery testing including charging/discharging cycles

- Inverter and HV component testing under EMC field conditions

- Shielded supply and signal paths to minimize interference

- Full integration into AIP-MCS, including data logging

- Flexibly expandable for customer-specific test requirements