The future of energy begins in the MEA.

Test fuel cells precisely, safely, and reproducibly – for maximum efficiency and innovative strength.

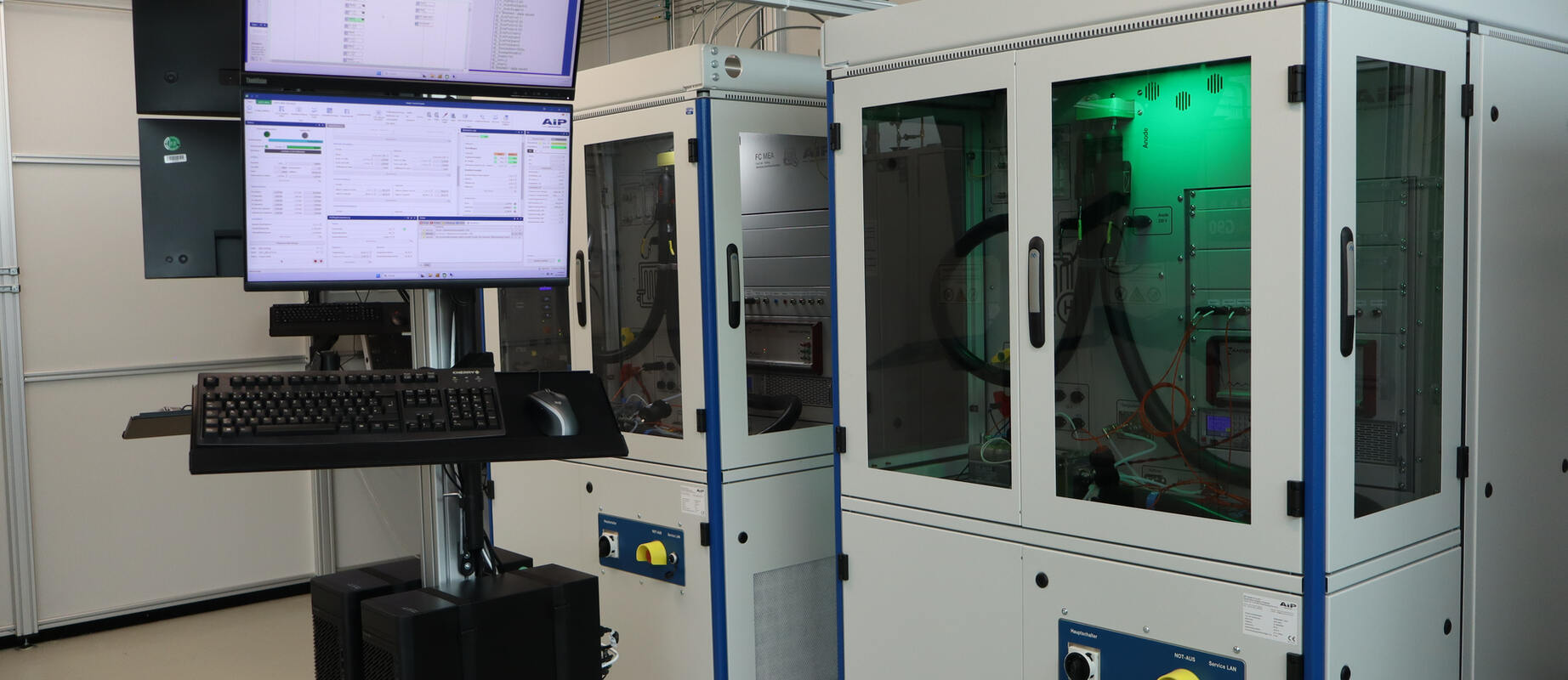

The H2FC test bench series was developed to test individual cells, stacks, or complete fuel cell systems under realistic, safety-critical, and highly precise conditions. The platform combines modular gas preparation, flexible humidity and temperature control, powerful diagnostic procedures, and a consistent SIL2-compliant safety concept into a universal test system. With automated sequences, sensitive measurement and control technology, and comprehensive data acquisition, the H2FC test benches offer an ideal environment for the analysis, validation, and further development of modern fuel cell architectures – from single cells to complex systems.

Advantages

- Modular & flexible: for individual cells and small fuel cell stacks

- Customized test bench solution for larger stacks and systems

- Precise parameterization: humidity, pressure, temperature, volume flows

- Fully automated: sequence editor, 24/7 operation, real-time control

- Comprehensive diagnostics: polarization curves, EIS, cell voltage monitoring

Application

- Research and development of new MEA materials and catalysts

- Performance and service life testing of stacks and systems

- Automotive fuel cells: load cycling, start-stop, accelerated aging

- Stationary fuel cells (continuous operation, humidity/temperature cycles)

- Quality testing, comparative testing, series development, and validation

From stack to system: test securely.

Precise gas flow control for realistic fuel cell conditions

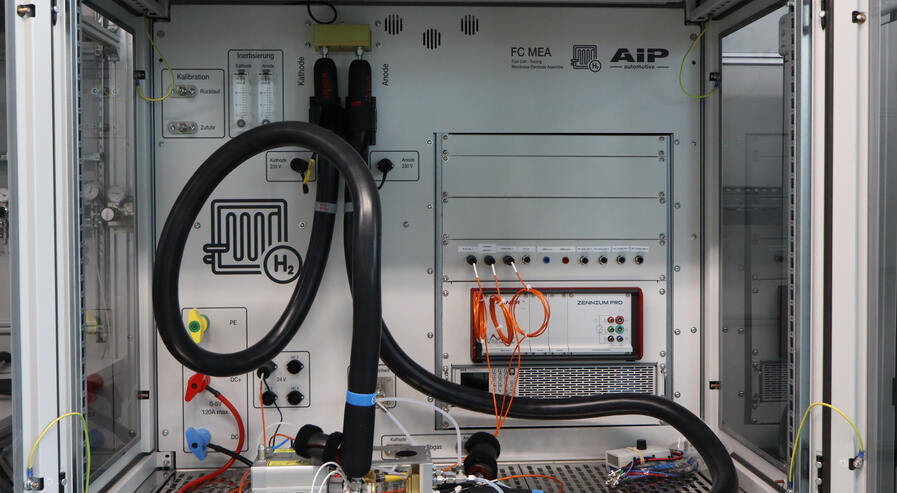

The H2FC provides a fully controlled environment for single cell or stack testing – with precise dosing of hydrogen and air, optionally expandable with oxygen, nitrogen, and contaminants. The system allows for precise adjustment of humidity, pressure, temperature, and volume flow to accurately replicate various operating conditions of a fuel cell – from dry high-temperature scenarios to humid low-temperature conditions.

Dynamic humidification, sensitive gas mass flow controllers, and stable temperature control form the basis for in-situ characterization, degradation and aging tests, as well as contamination and regeneration tests. Developers gain deep insights into activity, Ohmic, and diffusion losses, as well as degradation mechanisms in modern fuel cells.

Highlights

- Precise gas dosing for H₂, air, N₂, O₂, and contaminants

- Controlled humidity control with dynamic adjustment

- In-situ characterization, degradation and aging tests, as well as contamination and regeneration tests

- Realistic fuel cell conditions for research and development

Characterization methods for fuel cells

In-situ characterization of the MEA and stack

- Break-in/activation: Initial conditioning to achieve stable and reproducible cell and stack performance.

- Polarization curves: Determination of cell performance under various operating conditions (temperature, pressure, humidity, oxygen concentration).

- Linear sweep voltammetry (LSV): Measurement of hydrogen crossover current to evaluate membrane tightness and integrity.

- Cyclic voltammetry (CV): Determination of electrochemically active surface area (ECSA), double layer capacity, and hydrogen crossover.

- Electrochemical impedance spectroscopy (EIS): Analysis of resistances and time constants to identify limiting processes (e.g., charge transfer, diffusion, membrane resistance).

- Limiting Current Density (iLim): Determination of oxygen diffusion resistance (macro- and micropores).

- CO methods (stripping, displacement, capacity): Precise ECSA characterization, analysis of ionomer distribution and coverage on catalyst and carbon.

- Accelerated stress tests (AST): Accelerated aging tests for catalyst, support, and membrane (e.g., potential cycles, load cycles, OCV tests).

- Drive cycles: Realistic load cycles for investigating degradation behavior under practical conditions.

- Contamination tests: Investigation of tolerance and regenerability with regard to gaseous (e.g., CO, NH₃) and dissolved (e.g., metal ions) impurities.

- Regeneration: Protocols for restoring cell performance after contamination (e.g., air bleeding, N₂ purge, water flushing).

Highlights:

- Ideal for extended life, load, and start-stop tests

- Safe 24/7 automatic operation without monitoring requirements