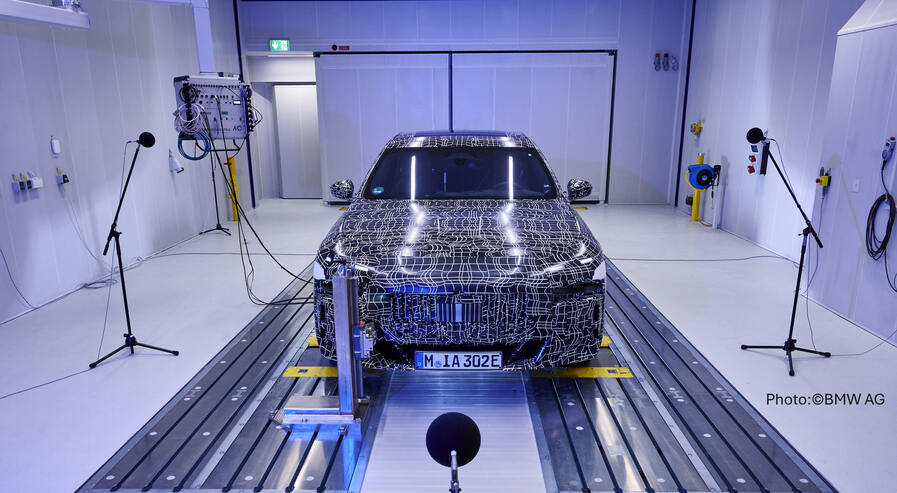

The benchmark for acoustic chassis dynamometer.

Reproducible NVH tests under real driving conditions – precise, stable, and acoustically unaltered.

The NVH roller test bench from AIP transfers real driving situations into an acoustically optimized laboratory environment – ideal for precise noise, vibration, and driving dynamics analyses. With individually controllable drive motors, vibration-optimized mechanics, and modern measurement technology, it forms the basis for reproducible, standard-compliant, and high-resolution NVH measurements. Vehicles of all drive concepts – from combustion engines to electric vehicles – can be tested and compared under precisely defined load and speed scenarios.

Advantages

- Acoustically optimized roller design for interference-free NVH measurements

- High dynamics and control precision thanks to individually controlled drive units

- Reproducible, realistic driving conditions including slip, load, and regenerative modes

- Safe test environment with integrated protection architecture and monitoring

- Easy operation and flexible integration into laboratory and test bench networks

Application

- Interior and exterior noise measurements according to ISO 362, ECE R51, GB 18697

- Evaluation of drive, inverter, and transmission noises (especially for BEV/HEV)

- Driving performance tests, functional validations, and rolling resistance simulation

- Analysis of vibrations, resonances, and mechanical structures

- Endurance, load cycle, and coast-down tests for research and series development

The benchmark for professional NVH noise analysis.

Interference-free NVH measurements thanks to sophisticated mechanics

The NVH roller test bench has been consistently designed for low-noise characteristics. The specially developed H-profile drum geometry prevents resonance and eliminates typical bell effects. The rollers run with low vibration and precise roundness, enabling high-resolution interior and exterior noise measurements – even at high speeds of up to 250 km/h.

The combination of vibration-isolated foundations, a torsion-resistant frame structure, and an acoustically optimized room concept ensures minimal inherent noise and a laboratory environment that accurately reflects NVH phenomena.

Highlights:

- H-profile drums without resonance effects

- Mechanical vibration isolation & sound-optimized structure

- Low inherent noise level – ideal for the most precise acoustic measurements

- Precise NVH analysis even at high driving speeds

Realistic vehicle dynamics for all drive concepts

Each roller is individually driven and controlled by a water-cooled electric motor – perfect for simulating front-wheel, rear-wheel, or all-wheel drive. Slip conditions, load changes, recuperation modes, or inverter-related noise phenomena can be precisely replicated.

The integrated inertia simulation allows adaptation to different vehicle masses and road conditions. This means that all driving situations – acceleration, coasting, constant speed, parasitic loss – can be simulated in a reproducible manner. Electric vehicles in particular benefit from the high control bandwidth for analyzing high-frequency noise components.

Highlights:

- Individually controllable 2WD/4WD drives

- Simulation of slip, load change, and energy recovery

- Inertia simulation for different mass classes

- Ideal for BEV/HEV-specific NVH phenomena

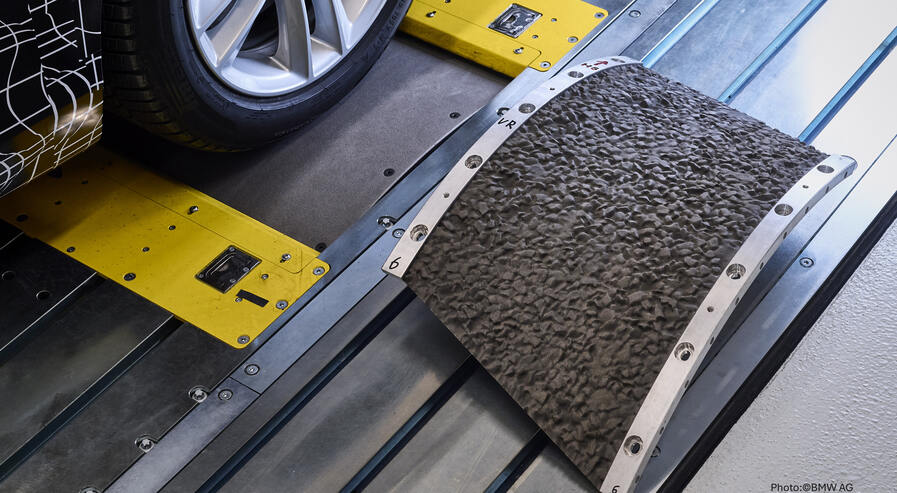

Simulation of road surfaces – customized for your test profile

The NVH roller test bench from AIP uses interchangeable surface shells that faithfully replicate real road surfaces: from rough asphalt and cobblestones to concrete or special surfaces. Thanks to these modular surface systems, any road profile can be simulated realistically – precisely tailored to the desired test scenario.

AIP manufactures the surface shells to customer specifications and precisely tailored to the test requirements – so that each roller becomes the desired road surface. This allows you to reproduce any road surface condition: urban coarse asphalt, cobblestones, hot-roll sections, or international standard surfaces – and easily replace individual surfaces when they wear out.

Highlights:

- Modular interchangeable surfaces (asphalt, paving, concrete, special surfaces, etc.)

- Realistic simulation of different road conditions for NVH tests

- Interchangeable surface shells – maximum flexibility and long service life

- Customized production according to customer profile – each roller becomes the desired road surface