Real driving dynamics—redefined for the laboratory.

From road profile to test bench scenario – without any external constraints.

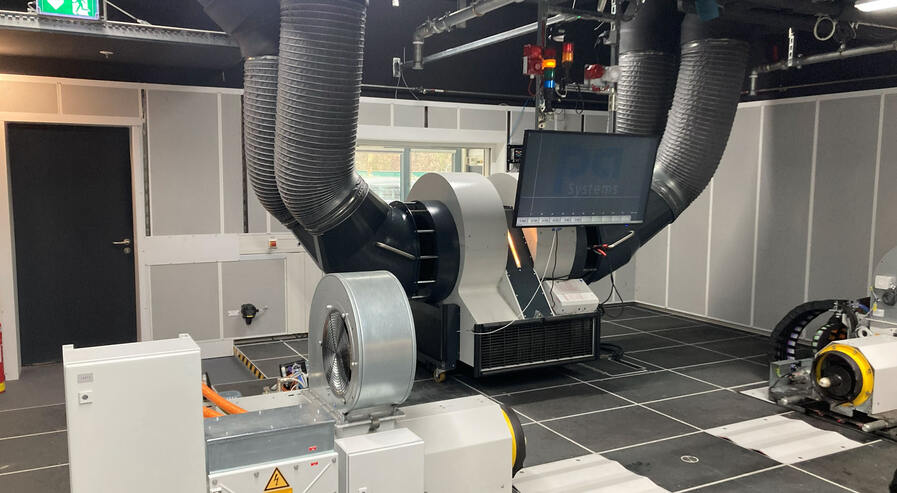

The AIP Road-2-Rig brings realistic driving conditions directly to the test bench. Test drives that previously had to take place on the road – subject to weather, traffic, or driver influences – can now be carried out daily, reproducibly, and safely in the laboratory.

Torque matching, GNSS integration, and virtual environment simulation allow real road load profiles to be accurately replicated. This results in reproducible test cycles that shorten schedules, reduce costs, and maximize development reliability.

Whether for powertrain development, consumption optimization, emissions assessment, or ADAS validation, Road-2-Rig combines the best of simulation and reality, enabling laboratory testing that was previously only possible on the road.

Advantages

- Reproducible load scenarios thanks to precise torque matching

- Massive time and cost savings due to fewer road tests

- Maximum safety for risky driving maneuvers and misuse tests

- Simulation + reality: GNSS, road load profiles, virtual worlds

- Flexible and modular for different vehicles, scenarios, and degrees of automation

Application

- Powertrain development (ICE, hybrid, BEV, e-drive, transmission)

- Emissions, fuel consumption, and range testing

- ADAS and OBD validations under reproducible conditions

- Misuse and off-road scenarios in a safe laboratory environment

- Back-to-back comparisons and benchmarking

Road-2-Rig: Bringing road reality to where progress happens.

Road loads precisely reproduced in the laboratory

The AIP Road-2-Rig accurately replicates real-world driving maneuvers in the laboratory by transmitting torque, load collectives, and speed signals via high-precision torque matching. This allows real-world route profiles – city center, highway, mountain passes, or stop-and-go traffic – to be varied and perfectly repeated, regardless of weather, traffic, or driver.

With Road-2-Rig, uncontrollable road influences are a thing of the past. Instead of tedious comparison drives, reproducible load conditions are now available at the touch of a button – ideal for development cycles, benchmarks, and validations.

Highlights:

- Precise torque matching for realistic load simulation

- Repeatable driving profiles for WLTP, US06, mountains, city & high speed

- Reproducible load changes, acceleration processes, and rolling phases

- Independent of traffic, weather, test drivers, or external conditions

- Perfect basis for development, OBD, and certification tests

Performing dangerous maneuvers in a controlled manner – without risk to the driver, vehicle, or surroundings

Road-2-Rig makes it possible to safely recreate high-risk maneuvers in the laboratory. These include misuse scenarios such as “idiot starts,” hard gear changes, full-throttle acceleration, clutch tests, and thermally critical continuous sequences.

The entire test environment is controlled, monitored, and independent of public roads. This means that even extreme scenarios that would be too dangerous or too rarely reproducible in reality can be reliably investigated. Prototypes are protected, development times are shortened, and validations are made safer.

Highlights:

- Safe execution of dangerous maneuvers (misuse, off-road, load jumps)

- No risk from the environment, traffic, or driver behavior

- High component protection through controlled load profiles

- Ideal for endurance testing, thermal management, and critical limit ranges

- Reproducible – critical sequences can be repeated exactly at any time

GNSS data, virtual routes, and ADAS scenarios – all controllable on the test bench

Road-2-Rig combines real driving data (GNSS, logger, RDE profiles) with virtual test environments. This allows complex ADAS scenarios, traffic dynamics, elevation profiles, or algorithmic coping strategies to be simulated in the laboratory – without a test track, without risks, and without measurement deviations.

For electric vehicles, state of charge (SoC) curves, thermal management, and recuperation strategies can also be compared under identical conditions. The system has a modular design and can be adapted to a wide variety of vehicles, test scopes, and degrees of automation.

Highlights:

- Virtualization of real driving routes using GNSS profiles

- Combinable ADAS and powertrain scenarios in a protected test environment

- Identical load curves for variant comparisons and back-to-back tests

- Ideal for e-drive development, recuperation, and thermal management

- Scalable from single units to complete vehicle test benches