EMC test bench for electric drives – realistic tests directly in the shielded chamber

With the increasing number of electric drive systems, the importance of electromagnetic compatibility (EMC) in research and development is growing. In order to test drives under realistic conditions in a shielded environment, the Becom Group (Bluetechnix) and AIP have jointly implemented a groundbreaking project: a fully electric motor test bench that is directly integrated into an EMC chamber. The solution significantly exceeds the requirements of the CISPR 25 standard and sets new benchmarks in measurement precision, flexibility, and test bench design.

EMC testing under real operating conditions – without compromise

With its growing portfolio of electric drives, Bluetechnix was looking for a solution that would enable it to test electric drive systems under load in a shielded EMC chamber – precisely where electromagnetic fields are controlled and measured. Conventional test benches usually place the drive unit outside the chamber and route signals through complex feedthroughs, which creates potential sources of interference and reduces measurement accuracy.

The objectives of the project included:

- Development of a fully electric drive test bench that operates directly in the EMC chamber

- Compliance with and significant underperformance of the CISPR 25 limits for interference emission

- A modular, expandable system that can later accommodate a second drive unit

- Minimal external interference thanks to an optimized EMC design

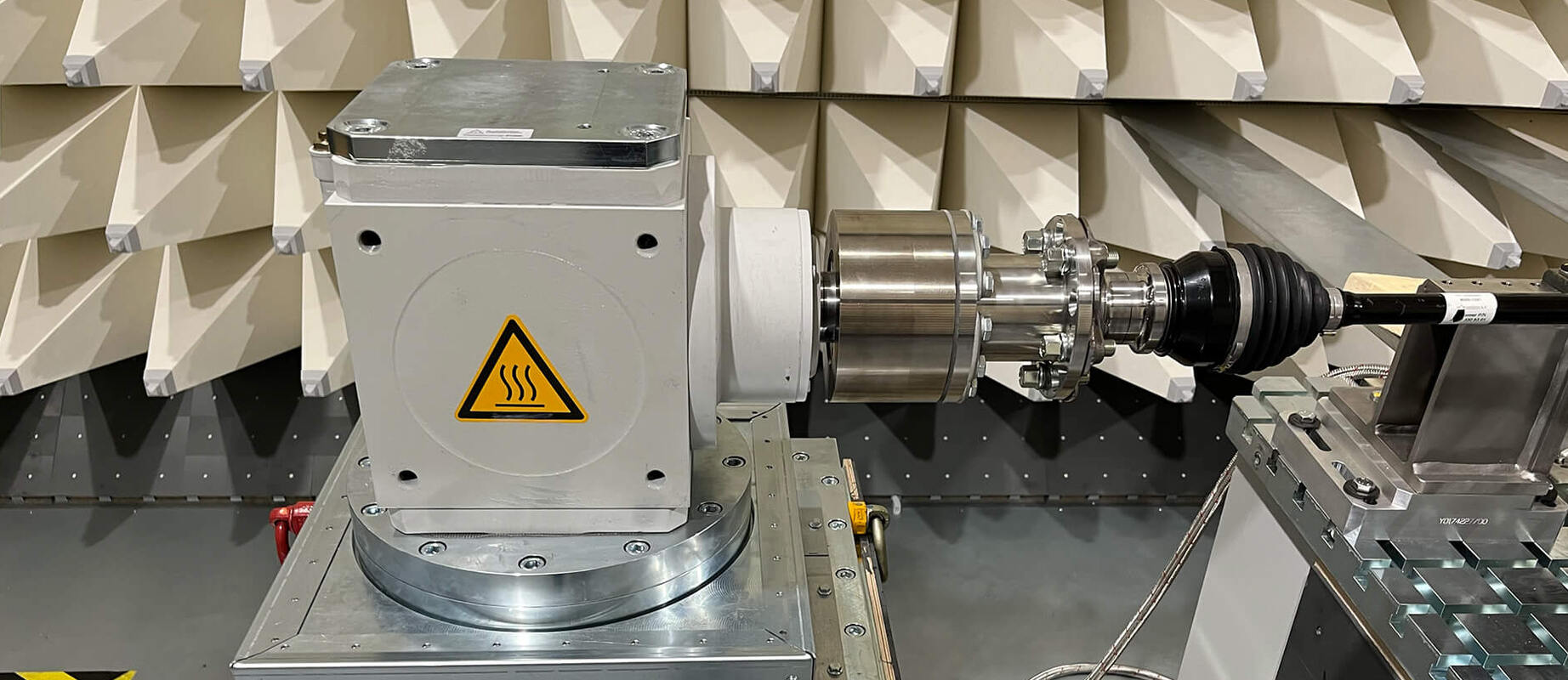

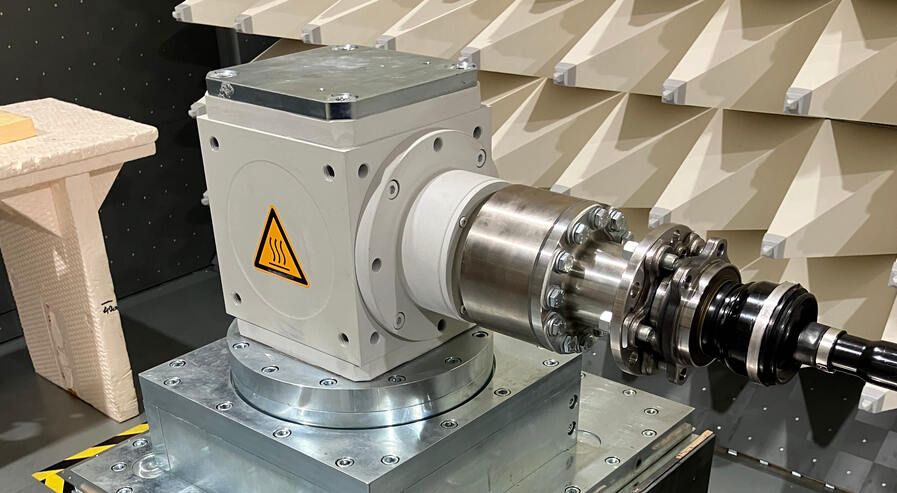

Electric powertrain test bench – compact, efficient, and metrologically precise

AIP designed a test bench with the entire electric drive unit installed inside the shielded EMC chamber. This eliminates the need for a conventional setup with an external test bench and complex feedthroughs – a concept that minimizes potential sources of interference and maximizes the accuracy of EMC measurements.

Key features of the solution:

- Direct integration of the drive unit in the EMC chamber reduces reflections and interference

- Vibration-decoupled base plate made of galvanized steel also serves as a conductive reference surface (CISPR-25)

- Electric machine with 120 kW continuous power (S1) and more than 3,000 Nm torque

- 1:1 angle gear for direct connection between drive and test object

- AIP automation system MCS for precise control of torque and speed

- Preparation for a second drive unit enables future expansions without modifications

Benchmark performance in EMC measurement – flexible, precise, future-proof

The test bench not only meets the technical requirements, but also demonstrates outstanding measurement results: The interference emission of the entire drive unit is more than 10 dB below the permissible CISPR 25 limits, as confirmed by joint measurements by Bluetechnix and AIP.

This was achieved through:

- High-quality shielding technology combined with a ferrite-based shielding architecture

- Carefully routed cables and EMC-optimized components

- An integrated, low-vibration test bench design

- Higher measurement precision and reproducibility due to the elimination of external feedthroughs

- Significant EMC improvement compared to conventional systems

- Maximum flexibility thanks to tool-free disassembly and reassembly in other chambers

- Future-proof thanks to expandability for more complex tests

- Lower operating costs thanks to electric instead of hydraulic drive technology