Hydrogen fuel cells are considered a key technology for a sustainable energy and mobility transition. Precise and realistic test conditions are essential to further improve their performance, efficiency, and service life.

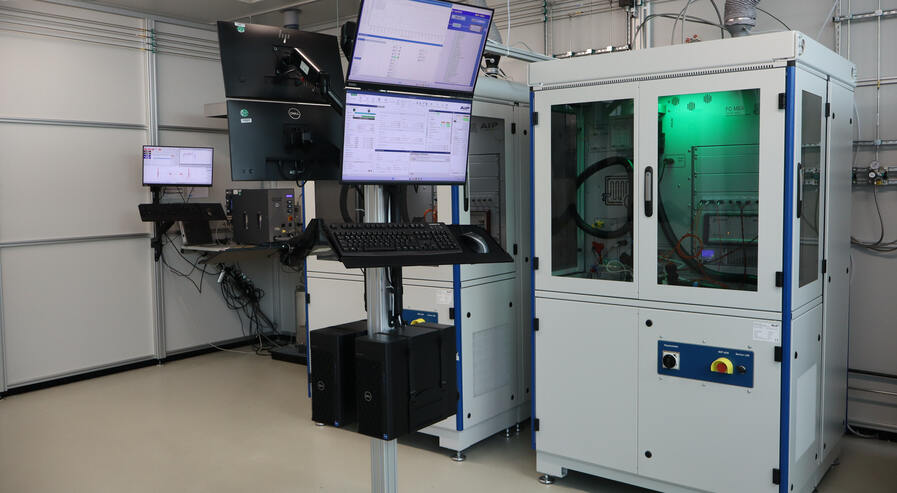

AIP implemented a customized test bench solution consisting of three state-of-the-art fuel cell test benches for the hydrogen laboratory at Kempten University of Applied Sciences. The project combines comprehensive hydrogen and automation expertise with many years of experience in special test bench construction and creates optimal conditions for research, development, and teaching.

AIP implemented a customized test bench solution consisting of three state-of-the-art fuel cell test benches for the hydrogen laboratory at Kempten University of Applied Sciences. The project combines comprehensive hydrogen and automation expertise with many years of experience in special test bench construction and creates optimal conditions for research, development, and teaching.

Flexible, precise, and reliable testing

Hydrogen fuel cells are considered a key technology for a sustainable energy and mobility transition. Precise, reproducible test conditions are essential to further improve their performance, efficiency, and service life.

AIP implemented a comprehensive test bench solution for the hydrogen laboratory at Kempten University of Applied Sciences, which can be used to test both individual fuel cell components and complete short stacks under realistic conditions.

The aim of the project was to specifically expand the existing laboratory equipment and create a flexible test environment that is equally suitable for research, development, and teaching. The focus was on the following requirements:

- High flexibility for different test specimens (MEA to stack)

- Precise control of all relevant process parameters

- Maximum safety when handling hydrogen

- Automated test sequences for long-term and endurance tests

- Intuitive usability for researchers and students

Customized test bench technology from AIP

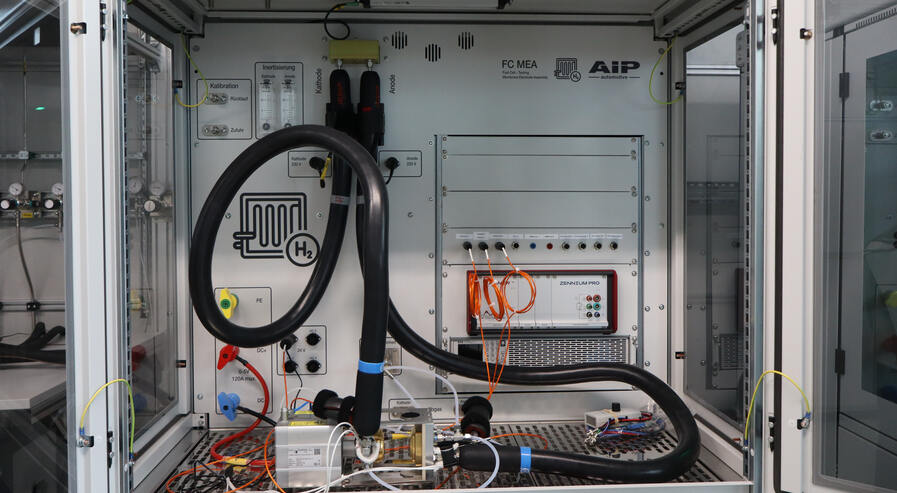

AIP developed and installed a total of three fuel cell test benches based on AIP's modular H₂ test bench technology and tailored precisely to the requirements of Kempten University of Applied Sciences.

A PEM fuel cell stack test bench and two MEA test systems for individual cells were used.

Technical highlights of the solution:

- PEM stack test bench (H2FC-STACK) for short stacks in the small to medium power range

- Two MEA test benches (H2FC-MEA) for detailed analysis of individual membrane electrode assemblies

- Precise gas dosing and humidification via mass flow controllers (H₂, air/O₂, N₂, contaminants)

- Temperature-controlled cooling circuits with DI water (approx. 0 °C to > 90 °C)

- Powerful electronic loads with currents up to 400 A

- Integrated potentiostat for electrochemical analyses (e.g., EIS)

- Automation via the AIP-MCS control system with seamless data acquisition

Future-proof testing environment for research and teaching

With the new test bench infrastructure, Kempten University of Applied Sciences now has a state-of-the-art and flexibly expandable test environment for hydrogen research. Experiments that were previously impossible or only possible to a limited extent can now be carried out under precisely defined and reproducible conditions – from short-term tests to automated endurance tests with dynamic load cycles.

The modular design of the AIP test benches allows for customer-specific adaptations and seamless integration into the existing laboratory infrastructure, such as central hydrogen and exhaust air systems. At the same time, students benefit from practical training in industrial test bench technology.

In summary, the project offers:

- Expanded research and testing opportunities for fuel cells

- High flexibility for changing test scenarios

- Reproducible, precise measurement results

- Maximum safety in hydrogen operation

- A sustainable, future-proof solution for research and teaching