Test benches for full E-power.

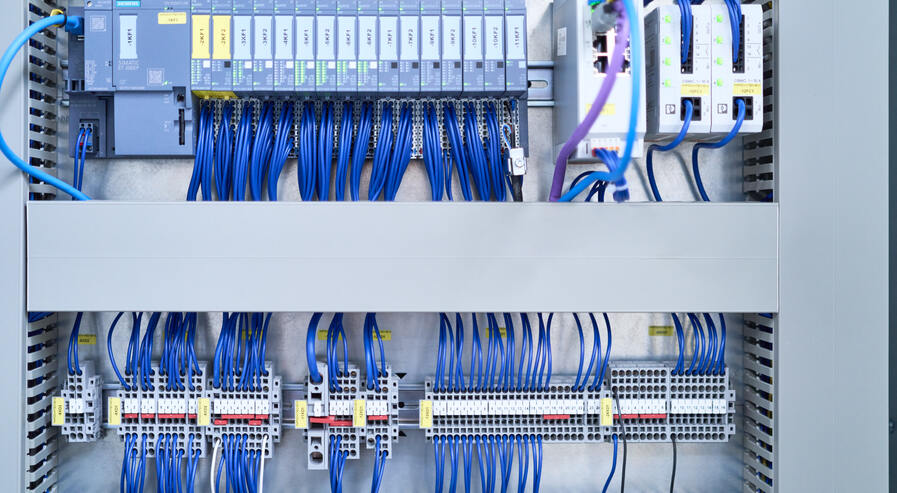

Modular battery test systems and battery simulation.

Batteries are at the heart of modern electromobility – their performance determines range, safety, and longevity. This increases the demand for precise and flexible test environments. AIP's battery test systems and battery simulators combine many years of testing expertise with state-of-the-art technology. They offer a fully configurable test field that accurately measures voltage, current, and temperature, and can be efficiently integrated into existing test benches via open interfaces and the DC link. Modularly expandable and customizable, they become central building blocks in development. The intuitive test bench software ensures clear visualization and easy data export – for fast, safe, and sustainable innovation processes.

Advantages

- High measurement accuracy for current and voltage

- Efficient energy use thanks to DC link

- Capable of charging and discharging thanks to bidirectional power modules

- High power density with existing SiC technology

- Scalable design for subsequent power expansion

- Comprehensive protection mechanisms for operators and test objects

Application

- Development of battery management strategies

- Safeguarding vehicle functions in the event of voltage drops or overload

- Investigation of cell and module behavior under various conditions

- Validation of fast charging processes – on the battery or on the vehicle

- Functional testing of electronic assemblies in production

- Safe reproduction of critical scenarios for analysis and troubleshooting

Validate batteries, ensure performance.

Flexible. Modular. Future-proof.

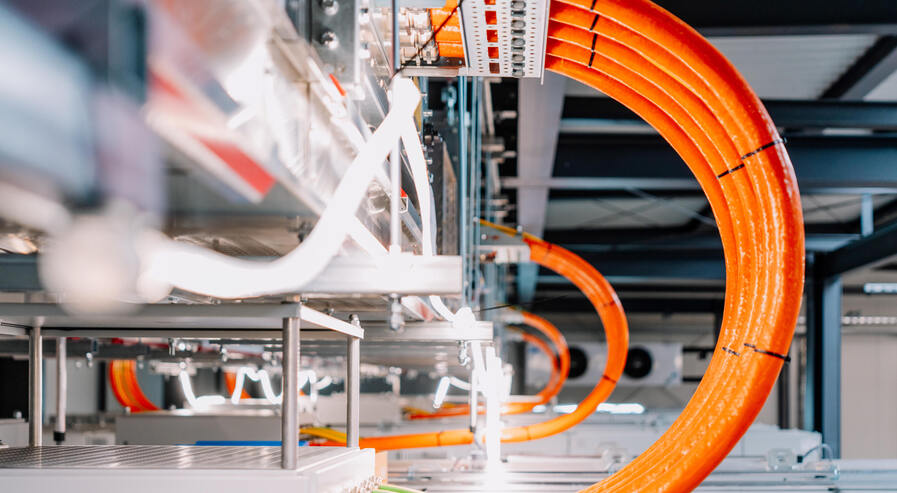

AIP's battery test systems and simulations precisely adapt voltage, current, and measurement ranges to your testing requirements. The modular design allows for flexible expansion as test objectives grow or higher power levels are required. The systems are available in various performance classes and can be flexibly adapted to different test requirements – from compact laboratory solutions to high-performance test benches for demanding automotive and industrial applications. This allows test bench environments to be efficiently adapted to growing requirements – for reliable results in research, development, and validation of modern energy storage systems.

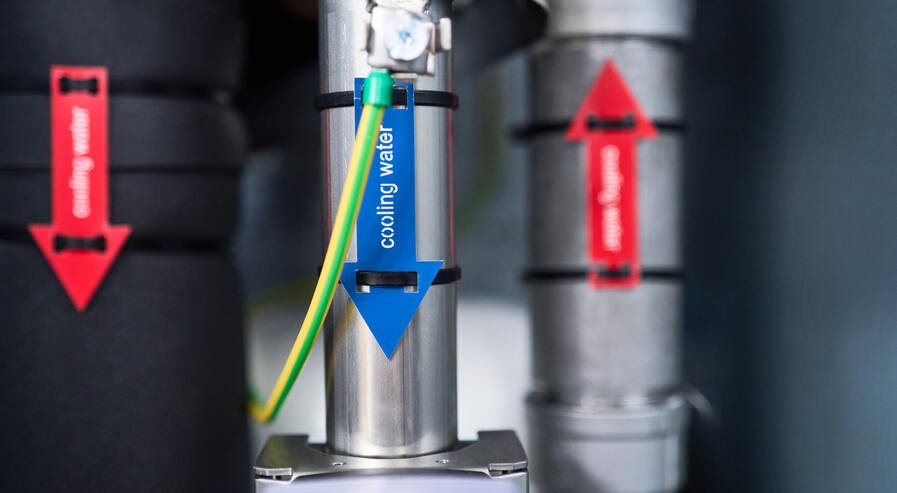

Energy efficiency

A DC link is a central component of modern battery test systems and simulations. It serves as a buffer between DC sources and consumers and performs several crucial functions:

- Reduces overall energy consumption and operating costs thanks to energy recovery

- Increases the precision and reproducibility of tests through a stable voltage and current supply

- Realistic simulation of dynamic load profiles, fast charging or discharging cycles, and complex test sequences

- Coupling of multiple load or source modules

- Thermal relief through the energy recovery function

Versatile use

AIP battery simulators are also ideal for use in charging technology. As a precise and flexible energy source, they can realistically simulate various charging and discharging profiles, enabling comprehensive testing of charging stations and fast charging systems.

In conjunction with charging solutions from AIP, the simulators are used directly as a reliable energy source and ensure a stable, controlled supply. This allows charging processes to be tested efficiently, different load scenarios to be simulated, and the performance of charging systems to be validated under realistic conditions.