Battery

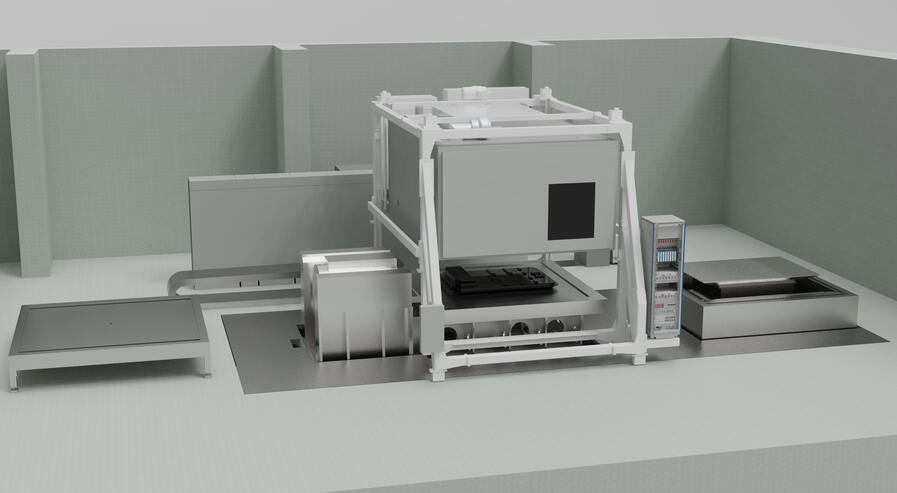

Ensure the development of resilient and certifiable battery systems – from prototype to series production. Batteries are the heart of modern drive systems. Their performance and safety determine the efficiency of your new masterpiece. Test batteries and complete energy packs under realistic conditions. Record charging and discharging cycles, temperature behavior, and aging precisely and reproducibly.

Full power. Full control.

Test the performance of your batteries under realistic conditions – from charging and discharging cycles to thermal behavior and aging. All systems are scalable and designed for high-voltage applications up to 1500V. Precise measurement technology and intelligent automation enable you to collect reliable data on efficiency, service life, and performance.

Test battery safety

Simulate short circuit, overload, and crush tests under controlled laboratory conditions. Integrated safety devices, thermal management, and automatic shutdown mechanisms ensure safe operation in every test phase. This allows you to test batteries reliably, reproducibly, and in compliance with standards – with maximum protection for personnel, test specimens, and equipment.

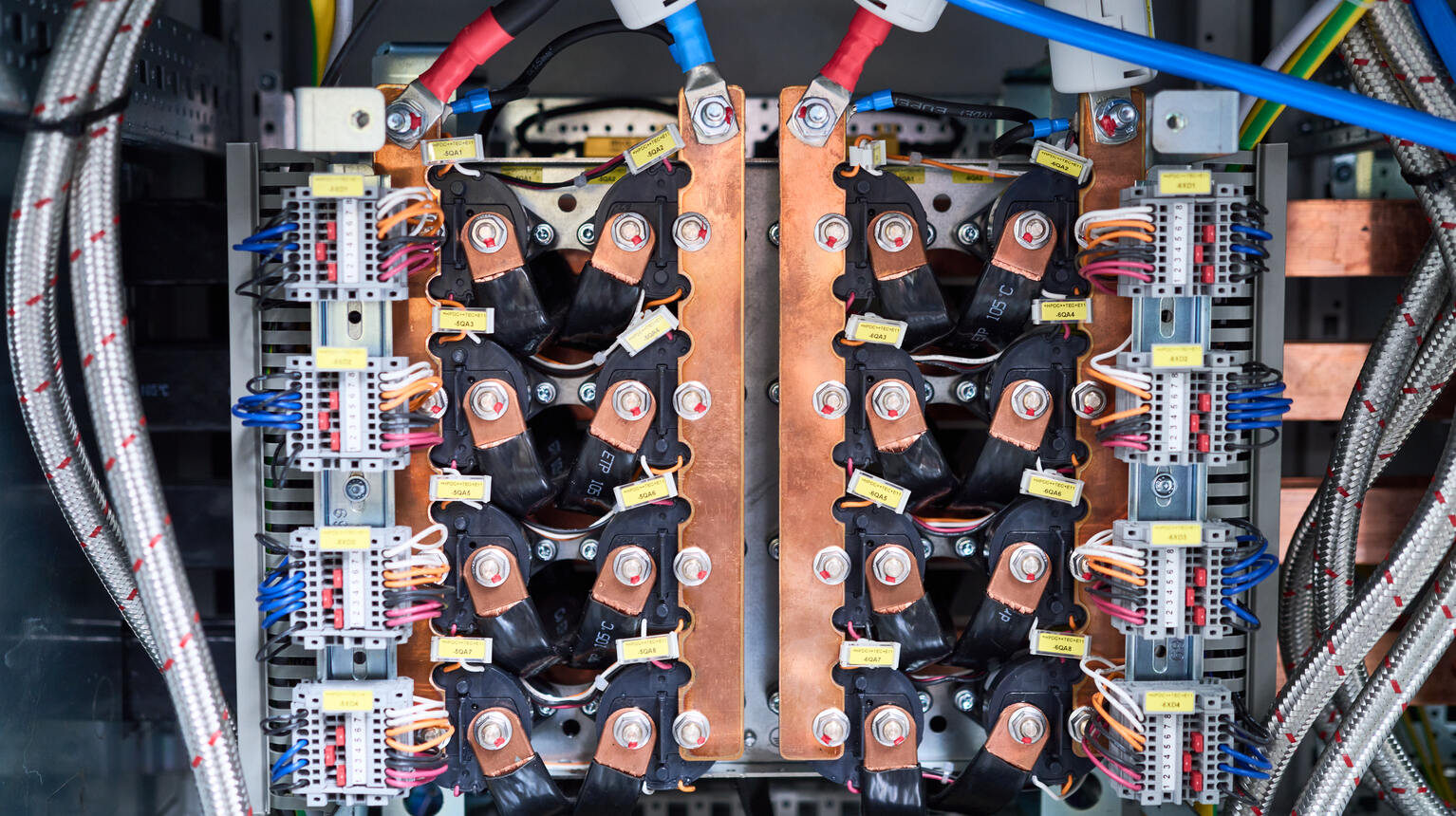

Charging infrastructure for vehicle batteries

They connect HV charging units and communication interfaces directly to your battery test bench, ensuring safe, accurate test procedures. Modular accessories adapt flexibly to different battery and pack concepts, allowing you to perform charging and discharging tests efficiently. Seamless integration reduces downtime and increases the quality of your development cycles.

Battery testing technology for every development stage – from pack to the complete battery.

Component testing – safety begins in the details

Analyze individual battery components in a targeted manner and in accordance with standards. Our systems enable precise testing of performance, temperature behavior, and safety—for efficient development and reliable integration into complex drive architectures.

Technical highlights

- Test benches for batteries and complete packs

- DC link for energy efficiency and cost reduction

- Measurement of charge/discharge cycles and temperature behavior

- Analysis of aging (state of health)

- Abuse test for batteries under safe conditions

- Scalable test systems up to 1500 V

- Compatibility with automated test sequences

Accessories – Interfaces that connect

Seamlessly integrate measurement technology and charging infrastructure into your battery test benches. Whether HV contacting, communication interfaces, or charging units: you can now use safe, efficient, and accurate test processes.

Simple testing

- Realistic charging and discharging profiles

- Reproducible tests for service life and efficiency

- Safe operation in high-voltage environments

- Flexible combination with other test systems

- Efficient test planning thanks to modular expandability

- Meaningful data for design and approval processes

- Time and cost savings in development and validation

- Optimized integration into existing test environments