The decisive role in your EMC validation.

EMC dynamomenter for realistic vehicle testing

AIP's EMC dynamometer enable realistic vehicle simulations in fully shielded EMC chambers. They generate highly precise and reproducible driving conditions while measuring electromagnetic emissions and the immunity of a vehicle under defined field strengths. Thanks to EMC-optimized drive technology and filtered power electronics, the test benches provide a reliable, standards-compliant basis for the development, validation, and homologation of modern vehicle technologies.

Advantages

- EMC-optimized drive technology with minimal interference emission

- Reproducible driving conditions for standard-compliant EMC measurements

- High-precision 4-motor technology for realistic single-wheel dynamics

- Scalable from motorcycles to 40-ton trucks thanks to different roller sizes and power levels

- Seamless integration of optional systems such as driving robots, turntables, or integrated safety functions

Application

- EMC measurements according to UNECE R10, CISPR standards, and international testing standards

- Development and validation of combustion engine, hybrid, and electric vehicles

- High-speed testing and load cycling with real driving resistance simulation

- Immunity testing under defined RF fields

- Research and approval testing in OEM, supplier, and institute laboratories

When real driving and precise EMC measurement come together.

Compact precision for passenger cars and light vehicles

AIP's light-duty EMC dynamometer are specially designed for passenger cars, compact electric vehicles, and sports models. With smaller roller diameters – typically ranging from 37.5 inches to less than 48 inches – a particularly low-interference environment is created. The more compact rollers reduce high-frequency radiation surfaces, allowing EMC measurements to be even more precise and reproducible. At the same time, they enable realistic driving resistance, high-speed ranges, and dynamic load mapping.

The 4-motor system, in which each wheel is driven or braked separately, reproduces single-wheel dynamics, ABS control, traction control systems, and all-wheel drive with high precision. In combination with EMC-optimized drive technology and filtered power and control lines, the test benches themselves generate virtually no interference signals – a decisive advantage for measurements in shielded EMC chambers.

This makes light-duty test benches ideal for modern vehicle developments, especially for powerful electric vehicles with a wide speed range and high dynamics.

Highlights:

- Optimized for passenger cars, sports cars, and light electric vehicles

- Smaller roller diameters (< 48") for minimized interference

- Precise individual wheel control via 4-motor technology

- Charging technology can be integrated into the turntable

- EMC-neutral drive technology for reproducible measurement results

Versatile & powerful – for modern commercial vehicles

The medium-duty roller test benches expand the concept of light-duty systems with higher load capacities, larger rollers, and more powerful drives. They are ideal for vans, SUVs, transporters, and medium-sized commercial vehicles, where higher masses, larger wheelbases, and wider ranges of application must be taken into account.

With robust rollers and powerful drives, load changes, acceleration phases, and constant speeds can be precisely simulated under defined EMC conditions. The precise control of all drive axles enables realistic simulation of all-wheel drives, hybrid drives, or traction strategies – an important factor for modern vehicle architectures.

Thanks to EMC-optimized filter and cable routing, the system remains interference-free even under high loads, enabling reliable measurement of how electronics and control units behave in realistic driving scenarios.

Highlights:

- For SUVs, vans, transporters, and medium-sized commercial vehicles

- Larger rollers for better tire contact and heat distribution

- High drive and braking power for dynamic tests

- Supports 4×2, 4×4, and hybrid drives

- Reproducible EMC measurements even under load changes

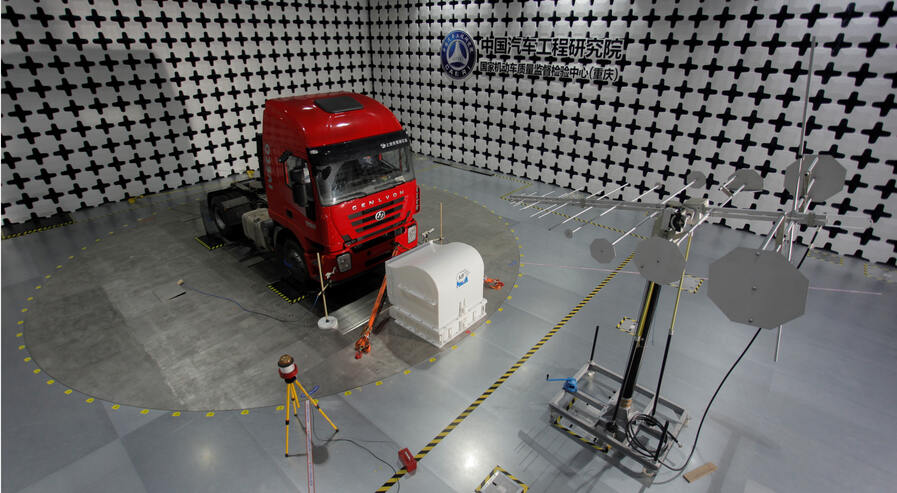

Maximum power and highest stability in heavy-duty applications

AIP's heavy-duty EMC dynamometer are designed for the extreme demands of heavy commercial vehicles. With roller diameters of up to 72 inches, load capacities of up to 30 tons per axle, and drive power in the megawatt range, even heavy trucks, buses, and special-purpose vehicles can be tested realistically and safely. Large rollers optimally distribute the contact area of the tires, reduce thermal loads, and enable long-lasting, realistic test drives under EMC conditions.

The powerful drives and eddy current brakes simulate high tensile forces, gradients, and dynamic load changes as they occur in real driving conditions. Braking forces of over 36 kN and enormous torques enable tests under full load – essential for modern electric trucks, fuel cell vehicles, or hybrid drives.

In addition, optional systems such as a large EMC turntable (e.g., 9 m Ø) for vehicle rotation, fire extinguishing systems, heavy-duty anchoring, and special safety mechanisms can be integrated to ensure maximum operational safety in the EMC chamber.

Highlights:

- For trucks, buses, special-purpose and heavy-duty vehicles

- Roller diameters up to 72" and axle loads up to ~30,000 kg

- Motor power in the megawatt range for extreme load simulation

- Braking forces over 36 kN for demanding test requirements

- Optional: EMC turntable, extinguishing systems, and heavy-duty safety technology

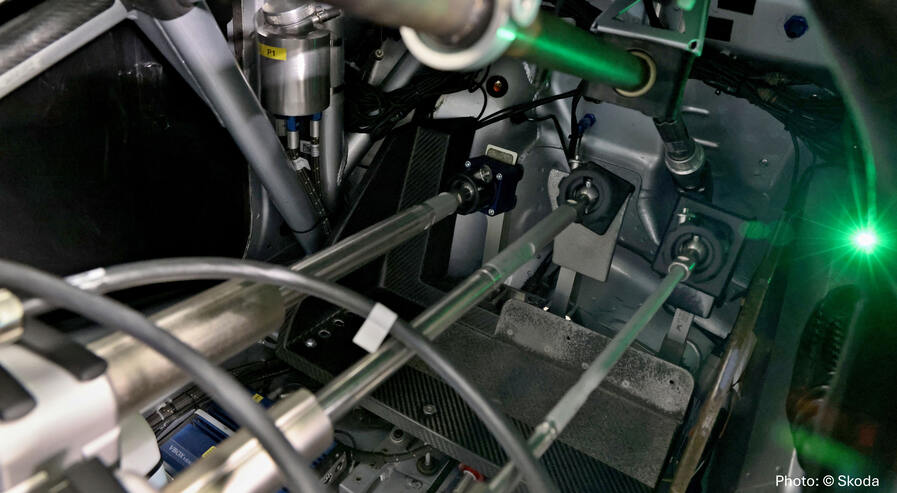

Precise vehicle control meets interference-free EMC performance

Automated vehicle control is not only convenient, but also essential for reproducible test procedures. To ensure that driving cycles run reliably and safely even under harsh EMC conditions, the P-JAMES pneumatic driving robot controls the accelerator, brake, clutch, and other controls completely free of interference. Its modular design allows it to be used in a wide variety of vehicles and ensures precise, repeatable driving profiles – for stable tests, realistic loads, and standard-compliant validation.