Understand emissions. Comply with limits.

Reproducible emission data as a basis for research, development, and homologation.

Stricter emission limits, new pollutant classes, and increasing requirements for measurement accuracy are fundamentally changing vehicle development. AIP offers a comprehensive portfolio of emission measurement systems for this purpose – from mobile RDE-PEMS to laboratory systems for gas, particle, evaporation, and brake dust measurements. All systems are ISO 17025 calibratable, legally compliant, and designed to meet current and future standards (Euro 7, China 7). This means they provide a reliable basis for type approval, research, and industrial quality assurance.

Advantages

- High-tech analytics: Maximum measurement accuracy thanks to NDIR, FID, CLD, QCL, CPC

- Compliant with standards and regulations: Developed for Euro 6/7, GTR No. 15/24, UNR No. 83/154/168/179, EPA 40 CFR Part 1065/1066 et al.

- Traceable: Through accredited ISO 17025-compliant calibration in the AIP calibration laboratory

- Modular & flexible: For every measurement task – gas, PN, PM, flow, et al.

- Easy integration: Interfaces via TCP/IP, AK protocol, CAN, OBD

Application

- Precise emission measurements for the analysis, optimization, and evaluation of new drive and exhaust concepts

- Standard-compliant emission measurements for the preparation and implementation of statutory approval procedures

- Reproducible emission tests for monitoring series conformity and process stability

- Mobile emission measurements under real driving conditions for the evaluation of realistic emission values

- Comprehensive recording of regulated emission sources, including exhaust, particulate, brake, and evaporative emissions

Technology for reliable type testing, clear measurement results and sustainable development processes.

Real-world emissions – accurately measured in driving conditions with PEMS EU7

The PEMS EU7 enables precise measurement of real-world emissions directly during driving. Gaseous pollutants and particle counts from 10 nm are measured in accordance with RDE standards. In the compact rear module, high-precision laser (LAS) and FID measurement technology combined with CPC technology deliver robust and reliable results for Euro 7 certification.

Highlights:

- Mounting on trailer coupling: No risk of contamination of the vehicle interior

- Modular design: Fast service and easy maintenance of the analyzers

- High-end gas analysis: Laser measurement technology (LAS) for CO / CO2 / NO / NO2

- High-end PN analysis: CPC measurement technology for particle counting

- Future-proof: Includes FID for HC measurement

- Proven EFM measurement technology for determining exhaust gas mass flow

dustIN – Euro 7-compliant brake emission measurement

The PMC-DI enables gravimetric particle mass determination of PM10 and PM2.5 in accordance with GTR 24 and UN R 179. Isokinetic sampling in combination with precise mass flow controller technology guarantees reliable and reproducible results. The SPC-DI provides particle number concentrations for SPN10, optionally TPN10, using proven CPC analysis and wear-free dilution stages. The available ISO 17025 calibration ensures traceable results and thus maximum process reliability.

Highlights:

- PM10 and PM2.5 measurement in a compact combination device

- Standard-compliant isokinetic sampling

- Precise mass flow controller technology

- PM and PN measurement technology in a compact 19-inch cabinet

- Efficient test bench operation thanks to multisampling system

- Coming soon: Filter change system for continuous PM sampling

LAS – Real-time measurement, direct and without cross-sensitivity

The LAS analyzer module (laser absorption spectroscopy) enables high-precision, time-resolved, and cross-sensitivity-free measurements of gaseous components such as NH3 or N2O (“additional pollutants”) in raw exhaust gas from combustion engines or similar applications. The detection of other components is also possible (e.g., CO, CO2, NO, NO2, CH2O).

Highlights:

- Direct physical measurement

- No cross-sensitivity, compensation-free measurement of gaseous components such as NH3 or N2O

- Large, dynamic measuring ranges with low detection limits (<0.1 ppm)

- Fast response time

- Large temperature and inlet pressure range for sample gases in combination with PreSampler unit

- Spectral correlation check, plausibility check of measured values

- No condensation, low adsorption effects

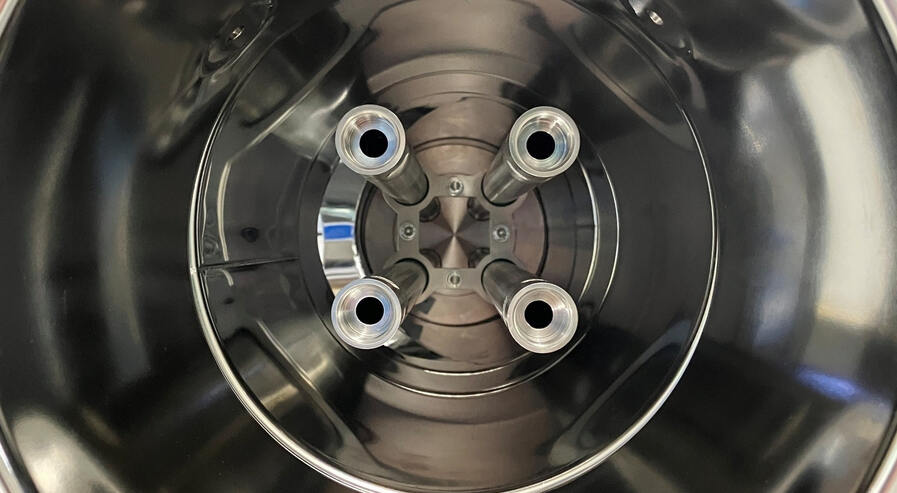

CVS – The international gold standard for exhaust gas dilution and type testing

In the field of homologation of vehicles with ICE or hybrid drive concepts, CVS (Constant Volume Sampling) technology continues to represent the gold standard in terms of exhaust gas dilution and volume flow measurement. In addition to gas conditioning, the CVS system also performs sampling of the gas sample for downstream gas analysis. The CVS system provides highly precise volume flow measurement and volume determination as a basis for determining the mass of the gas components contained or the particle load present in the exhaust gas. Critically operated Venturi nozzles guarantee robust system operation and ensure maximum measurement accuracy.

Highlights:

- Minimal footprint

- Application-specific throughput levels can be achieved

- High-performance version up to 60 m³/min (3600 m³/h)

- Split cabinet concept: Excellent accessibility for maintenance, service, and calibration work

- Minimal gas downtime thanks to simultaneous filling, analysis, flushing, and evacuation

- Modular upgrading possible, e.g., dilution air preheating, boost blower

QCL for accurate N₂O measurements – laser precision for modern emission limits

The QCL system measures N₂O selectively, without cross-sensitivity and with detection limits <10 ppb. Developed for WLTC, FTP-75, Euro 7, GTR 15, and international certification standards. Ideal for validating exhaust aftertreatment systems.

Highlights:

- QCL technology, <10 ppb LOD

- No chip calibration

- Modular for EMS systems or stand-alone

- Perfect for engine and roller test benches

CANARY activated carbon filter loading – fully automatic & reproducible

CANARY simulates real tank emissions through automated butane/gasoline loading and air purging. A must for SHED tests and international evaporation regulations (CARB, EPA, EU).

Highlights:

- Modular design: Multi-station operation with central control unit

- Load rate and mixing ratio freely adjustable via mass flow controller

- Plausibility and monitoring functions (HC warning unit, exhaust air flow monitoring, leak test)

- Interchangeable measuring equipment for minimal downtime due to maintenance and calibration