Aero

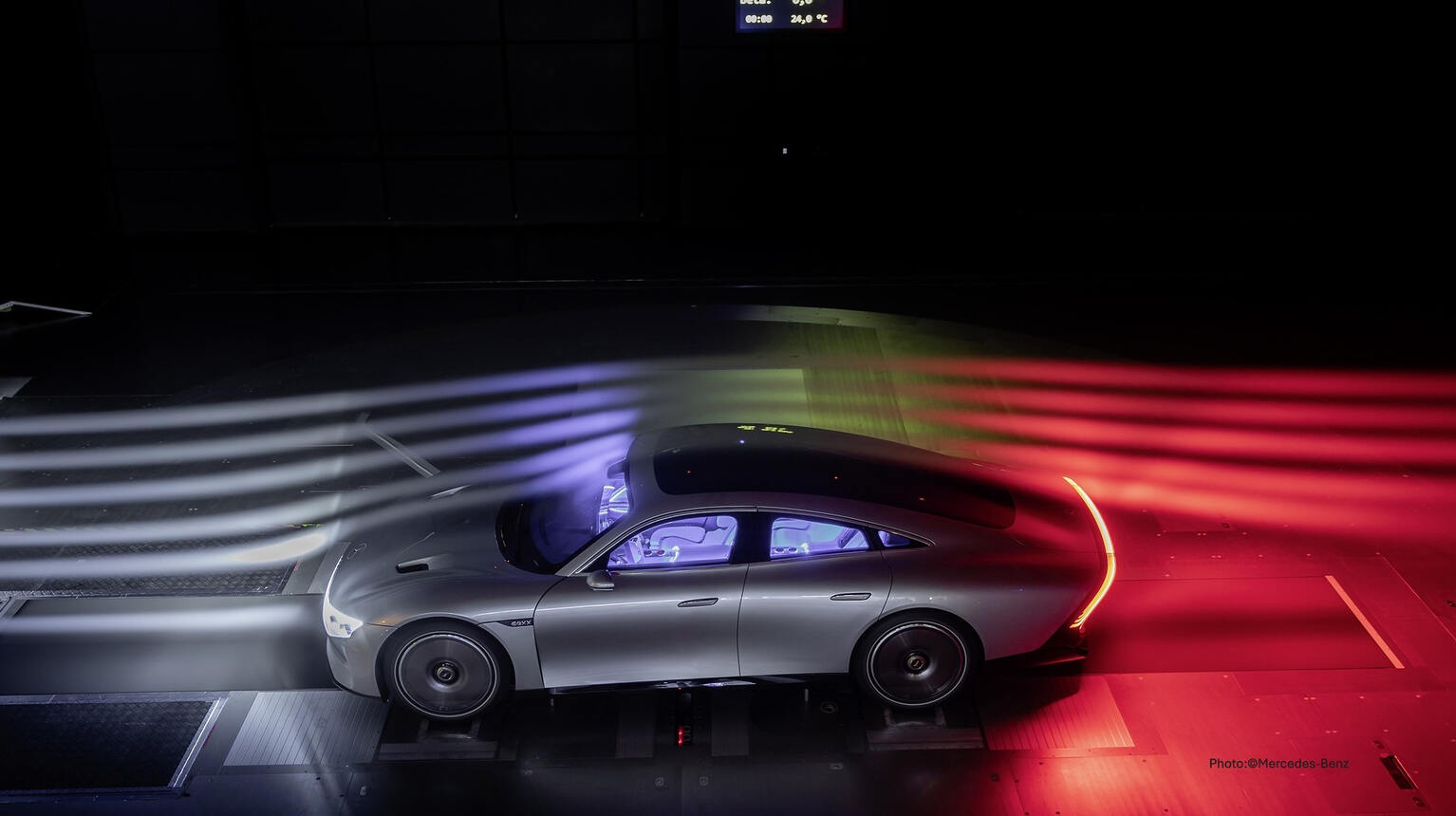

Greater efficiency, comfort, and optimized driving performance. Use our AERO test benches to obtain reliable data for optimizing fuel consumption, range, and noise behavior – in a real aerodynamic environment. Roll systems, wind flow units, and thermal modules enable the precise measurement of data for cooling air flow, heat dissipation, or rain/snow behavior under laboratory conditions. Just like outside – only indoors. The hybrid of a classic wind tunnel and test field.

Precise aerodynamics under realistic conditions

Measure aerodynamic forces and moments as realistically as possible. The combination of a wind tunnel balance and a “rolling road,” the treadmill system underneath, enables accurate, reproducible data for optimizing efficiency, range, and driving stability – under conditions that are almost identical to real driving.

Windy here.

Simulate every driving situation precisely in the wind tunnel – regardless of wind and weather – and analyze aerodynamics, aeroacoustics, and driving comfort more efficiently than ever before. Distinguish between wind and rolling noise simultaneously for the first time and still examine the results in detail. Advances in the development of quiet electric vehicles. Automatic module changes also shorten test times and increase the efficiency of your development processes.

Heat-cold tested

Test your vehicles under realistic conditions in wind tunnels, climate chambers, and altitude chambers. The multi-motor concept ensures maximum dynamics and efficiency, whether in freezing cold or tropical heat. From –40 °C to +60 °C, at speeds of up to 300 km/h, anything is possible.

Air resistance against testing is futile.

Air flow measurement & Co. for the highest demands

A precise airflow meter allows you to accurately analyze flow behavior and airflow on the vehicle. This enables you to optimize aerodynamic properties, minimize energy losses, and accelerate development processes. As a manufacturer, you gain the data you need to improve your products. Simulation, validation, and quality control ensure efficiency, performance, and compliance with standards throughout the entire development cycle.

Technical highlights

- Wind tunnel balance

- Combination of roller system, wind flow unit, and thermal modules

- Measurement of air resistance, lift, and lateral forces

- Precise analysis of aeroacoustics and noise generation

- Simulation of real environmental conditions (rain, snow, temperature)

- Adjustable air speeds and flow profiles

- Integration of air conditioning and energy management

- Modular design for different vehicle sizes

- Interfaces to external measurement and data acquisition systems

Efficiency calling.

Harness the power of wind in complex development processes. With modular concepts, high efficiency, and standard compliance, you can secure your projects with our AERO test benches.

Simple testing

- Precise measurement of air velocity and distribution on vehicles and components

- Optimized aerodynamics for lower air resistance and energy consumption

- Improved driving stability through targeted control of flow patterns

- Reproducible test results for development and validation processes

- Faster identification of aerodynamic weak points

- Reduced effort for real-world driving tests thanks to precise laboratory data

- Ensuring compliance with standards in exhaust and consumption tests

- Data-based foundation for design and construction decisions

- More efficient development cycles through automated measurement data acquisition

- Better comparability between prototypes and series models

- Lower development and operating costs through early fault detection