Automation

Make complex test processes easy to manage – with the combination of AIP MCS and AIP RTCU, you can automate your test benches holistically, efficiently, and future-proof. Our platform combines measurement data acquisition, real-time control, and central control in an open, scalable system.

Together, RTCU and MCS enable consistent, high-precision, and scalable automation – from local control to higher-level process logic. Standardized interfaces, intuitive user interfaces, and automated processes ensure maximum efficiency, reproducibility, and safety. Whether R&D or end-of-line: With AIP, you can automate your test benches flexibly, reliably, and future-proof.

MCS – Master Control System

Central platform for controlling and monitoring all relevant processes in one system. The MCS enables flexible integration into existing systems and IT structures, automates recurring processes, and offers an intuitive, clear user interface for efficient monitoring and fast response times.

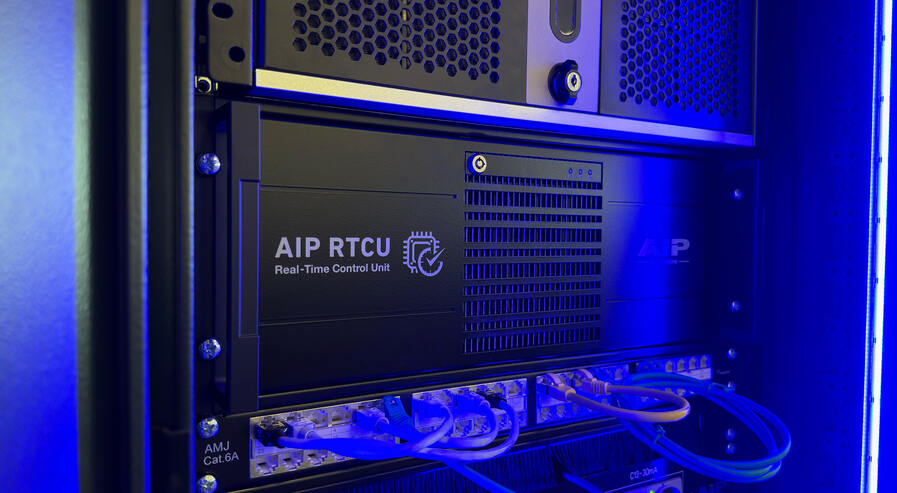

RTCU – Real Time Control Unit

High-precision hardware unit for real-time control of dynamic test sequences. The RTCU operates deterministically and synchronously, ensuring reproducible results and enabling precise control even with highly dynamic load and control profiles thanks to minimal latency.

Functional safety

Intelligent safety: Integrated functional safety mechanisms enable the system to continuously monitor relevant limit values, respond using graduated escalation logic, and establish defined safe states in the event of a malfunction. This provides optimum protection for the test bench, test object, and operator – without compromising performance or availability.

Automation without limits

Technical integration without limits

The AIP automation platform combines control and regulation, measurement data acquisition, and operation in an open, scalable architecture. Test processes are centrally controlled, automated, and monitored in real time—securely, reproducibly, and efficiently.

At the heart of the system are MCS and RTCU – a high-performance real-time control and monitoring system optimized for automotive test benches and beyond. Freely configurable controllers, setpoint tables, limit value monitoring, and calculations enable precise and highly dynamic test sequences.

Efficiency through intelligent process control

System advantages at a glance:

- Central control of complex test systems

- Real-time monitoring of critical parameters

- Automated test sequences for reproducible results

- Integration through standardized interfaces

- Freely configurable and adaptive user interfaces and process visualization

- Modular design for easy expandability

- Optimized for test bench automation